200 Hydrophilic & 100 Hydrophobic

GREENFLEX 200 (Hydrophilic) & GREENFLEX 100 (Hydrophobic)

Method of statement Two pass system

- Identify the source(s) of leakage.

- Water Leakage Condition of Diaphragm Wall:

- Gushing and visible water film: GREENFLEX 100 (Hydrophobic)With GREENFLEX 200(Hydrophilic) will be applied.

- Clean the crack and the surroundings thoroughly and remove all dust, and friable and deleterious materials with an air blower.

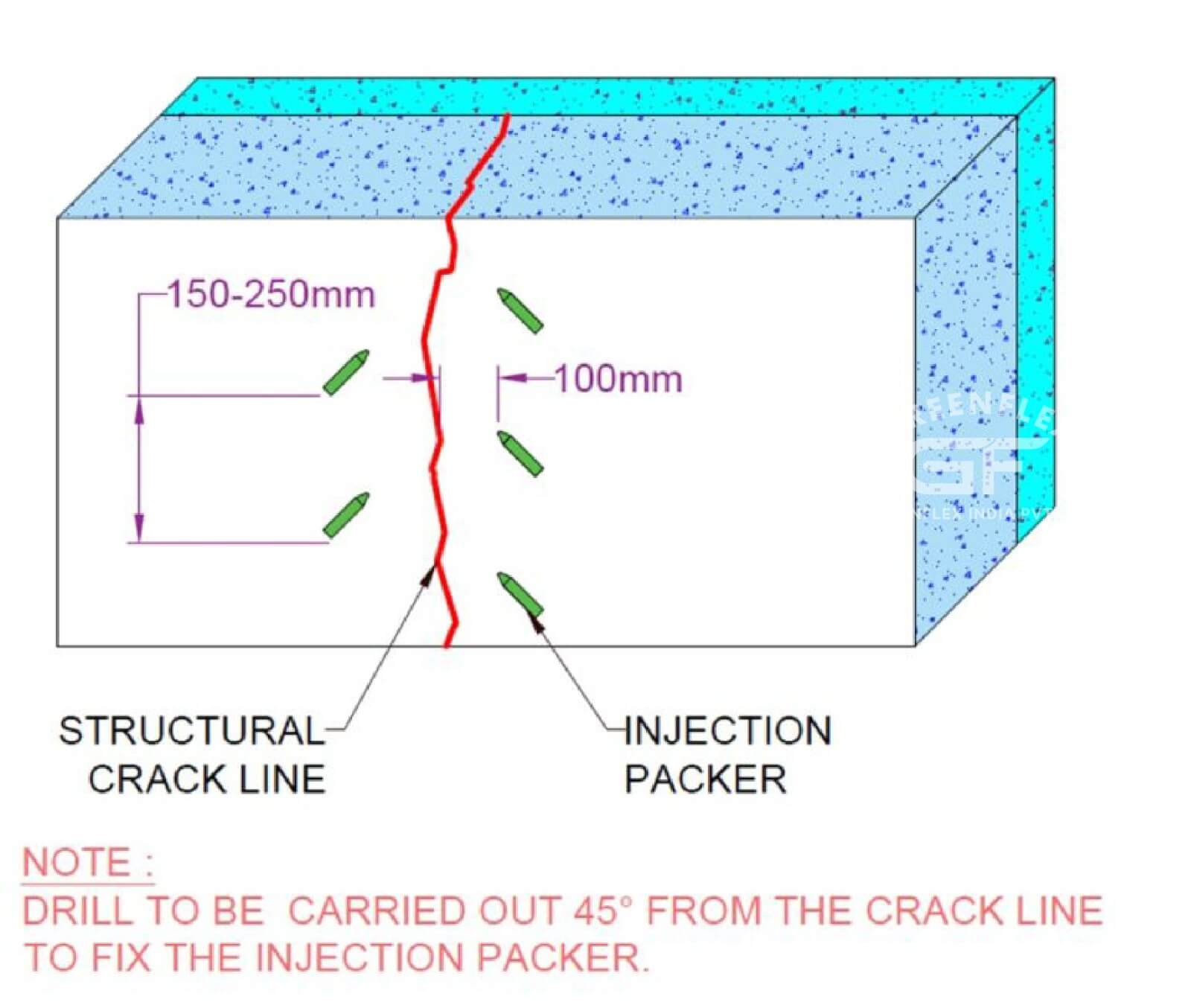

- Drill injection points at a distance of 150 mm~300 mm to the cracks. The injection drilling depth depends on the cracks and leaking conditions.

- Drilling into the Wet crack lines 45 degrees into the surface and towards the crack using a 10 mm or 14mm Diameter SDS Drill bit.

- Insert a non-return valve packer 9mm or 13mm into the hole and tighten it with a spanner.

- Load the pump with GREENFLEX 100(Hydrophobic) into the packer. Wait about 15 to 20 minutes for the GREENFLEX 100 reaction.

- Thereafter second part of pumping GREENFLEX 200 (Hydrophilic) to the same packers and stop pumping when the resin is emitted from the crack. Wait about 15 to 20 minutes for the GREENFLEX 200 reaction.

- Maximum pressure should not exceed 70 to 200 bar.

- Must Stop the injection when the pressure level exceeds 200 bars.

- The water leakage repair work is completed.

- Upon conclusion of the injection and the curing process of the grouting cut out exposed packer head and patch with non-shrink grout cement. Housekeeping work will be done after the completion of repair works.

Method of statement Single pass system

- Identify the source(s) of leakage.

- Water Leakage Condition of Diaphragm wall:

- Damp and visible water film: GREENFLEX 200(Hydrophilic) will be applied.

- Clean the crack and the surroundings thoroughly and remove all dust, and friable and deleterious materials with an air blower.

- Drill injection points at 150 mm~300 mm to the cracks. The injection drilling depth depends on the cracks and leaking conditions.

- Drilling into the Wet crack lines 45 degrees into the surface and towards the crack using a 10 mm or 14mm Diameter SDS Drill bit.

- Insert a non-return valve packer 9mm or 13mm into the hole and tighten it with a spanner.

- Load the pump with GREENFLEX 200(Hydrophilic) into the packer.

- Maximum pressure should not exceed 70 to 200 bar.

- Must Stop the injection when the pressure level exceeds 200 bars.

- The water seepage repair work is completed.

- Upon conclusion of the injection and the curing process of the grouting cut out exposed packer head and patch with non-shrink grout cement. Housekeeping work will be done after the completion of repair works.

Greenflex Grouting Injection Method Diagram

GREENFLEX 200 (GEL) &GREENFLEX 100 Hydrophobic

Method of statement Two pass system

- Identify the source(s) of leakage.

- Water Leakage Condition of Diaphragm wall

- Gushing and visible water film: GREENFLEX 100 HYDROPHOBIC With

- GREENFLEX 200(GEL) will be applied.

- Clean the crack and the surroundings thoroughly remove all dust, and friable and deleterious materials with an air blower.

- Drill injection points at a distance of 100 mm~150 mm to the cracks. The injection drilling.

- depth depends on the cracks and leaking conditions.

- Drilling into the Wet crack lines 10mm Diameter SDS Drill bit.

- Insert a non-return valve packer 9x95mm or 9x150mm into the hole and tighten with a spanner.

- Load the pump with GREENFLEX 100(HYDROPHOBIC) into the packer.

- Wait about 10 to 15 minutes for the GREENFLEX 100 reaction. Thereafter second part of pumping GREENFLEX 200 (GEL) to the same packers and stop pumping when the resin is emitted from the crack.

- Maximum pressure should not exceed 150 to 200 bar.

- Must Stop the injection when the pressure level exceeds 200 bars.

- Upon conclusion of the injection and the curing process of the grouting cut out exposed packer head and patch with non-shrink grout cement.

- Housekeeping work will be done after the completion of repair works.

Method of statement Single pass system

- Identify the source(s) of leakage.

- Water Leakage Condition of Diaphragm wall

- Damp and visible water film: GREENFLEX 200(GEL) will be applied.

- Clean the crack and the surroundings thoroughly remove all dust, and friable and deleterious materials with an air blower.

- Drill injection points at 100 mm~150 mm to the cracks. The injection drilling.

- depth depends on the cracks and leaking conditions.

- Drilling into the Wet crack lines 10mm Diameter SDS Drill bit.

- Insert a non-return valve packer 9x95mm or 9x150mm into the hole and tighten with a spanner.

- Load the pump with GREENFLEX 200(GEL) into the packer.

- Maximum pressure should not exceed 150 to 200 bar.

- Must Stop the injection when the pressure level exceeds 200 bars.

- Upon conclusion of the injection and the curing process of the grouting cut out exposed packer head and patch with non-shrink grout cement.

- Housekeeping work will be done after the completion of repair works.

Get in Touch With Our Experts

we are committed to delivering excellence in PU Injection Grouting with innovative materials, methods, and standards.